High Power Charging is a relatively hot topic and one of our many cutting edge subjects. This content is actually not very good to talk about because there is a lot involved and it is a systematic topic. I'll start talking about it below in accordance with my personal facet-to-point way of thinking.

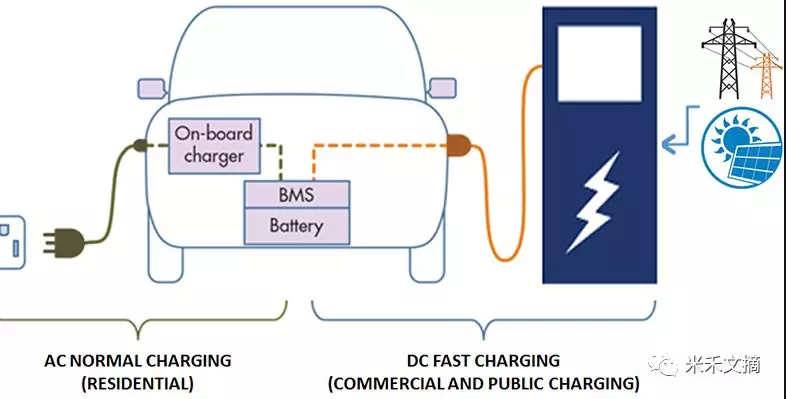

The process of charging is the process of sending electricity from the grid to the car battery. Whether you use AC charging at home, or DC charging at the mall or on the highway, you are transferring electricity from the grid to the car battery for storage, because the battery can only store DC electricity, so generally AC electricity cannot go directly to the battery.

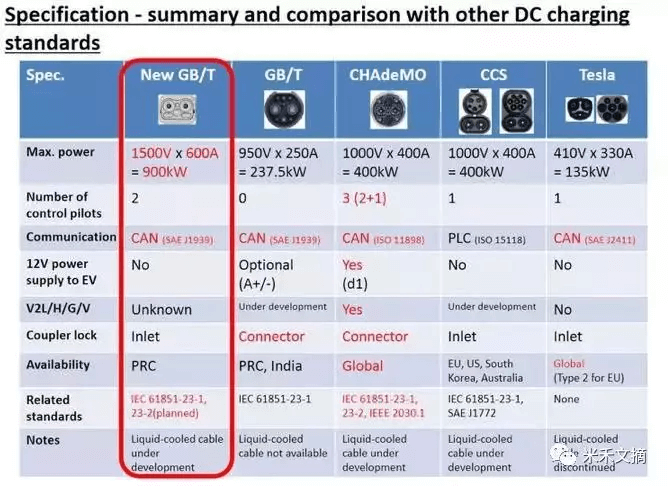

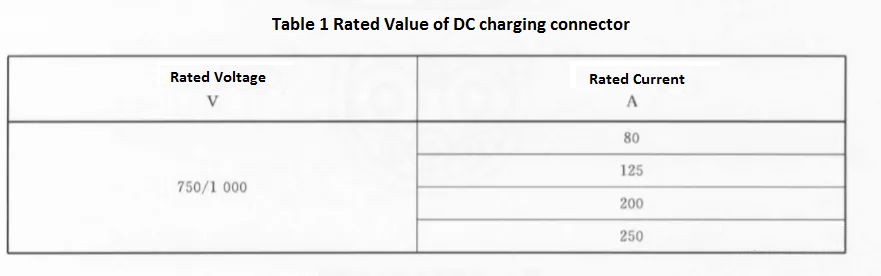

What is high power? High power is relative, power is determined by voltage and current, so high power can basically be understood as an increase in these two indicators; there is currently no clear definition of the power range of high power, we can see that Europe and the United States is generally defined at 350KW (1000v, 350A) and Tesla also defines its high power charging at 350KW or even higher; Our future standard is likely to be defined as 1500V*600A/900KW(max power), according to the 2015 version of the standard, the maximum voltage of the current charging port is 750/1000V and the maximum current is only 250A; and our high power charging is likely to be developed jointly with Japan in the future.

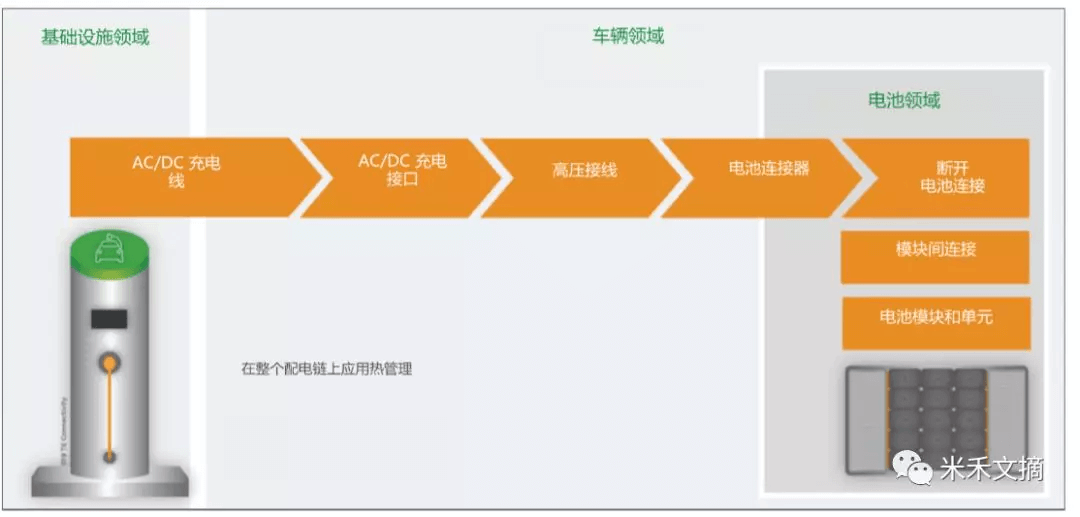

Both sides of the power charging system

We divide the charging system into the vehicle side (EV) and the charging facility side (EVSE) to see, this involves more associated enterprises, for example, in the EVSE side, there are power grids, charging facility manufacturers, charging operators, etc., any one of these enterprises can be singled out and Europe and the United States to do a comparison to write something, because the content is too much, do not expand the narrative for the time being; high-power charging on the grid challenges, the Many people have a lot of worries, for example, the grid load is not enough, the utilization rate is not high enough, in fact, I think the challenge to the grid is not so exaggerated, and no matter what, advance research is always good, do not wait for Europe and the United States are done with the technology, we have to catch up again. But still need to co-ordinate the planning and layout, which I think the Japanese approach is to refer to the government to co-ordinate management, OEM joint establishment of companies responsible for operation and maintenance, not blindly on; and then look at our domestic practice is also not rash on high-power pile, more is the alliance of enterprises such as "school enterprises" experiment This is much better than in the past, and we have not seen some OEMs join in the investment and research of the facilities, which is a better phenomenon; because this industry is originally a system industry, unilateral It is not enough to do research on the EVSE side.

The impact of high power charging on cable and charging interface manufacturers

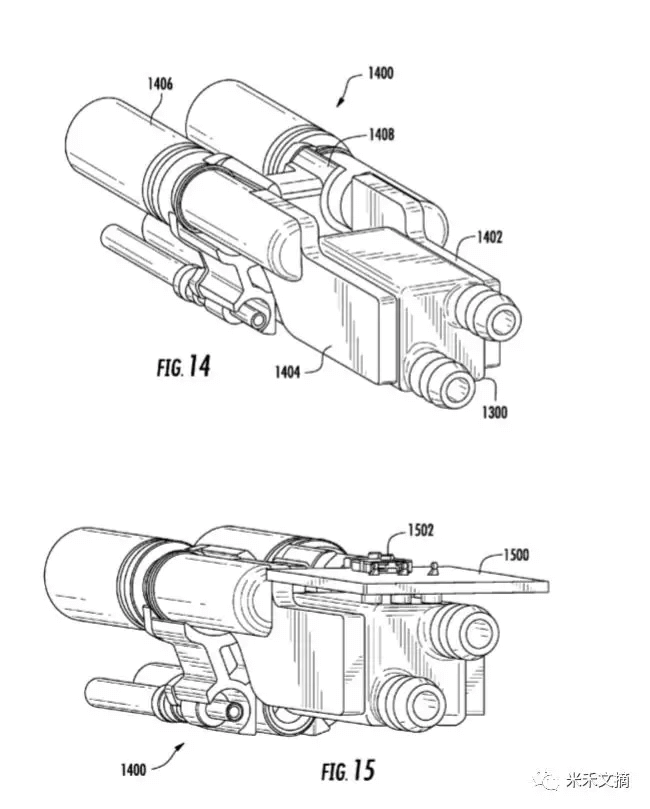

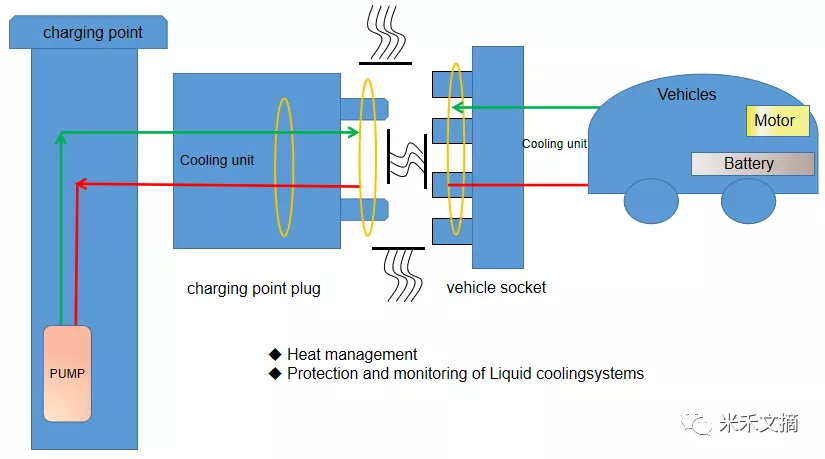

The current standard according to the DC interface rated voltage and current to calculate 250KW (1000V/250A) cable diameter is at least 70 flat, if the future of our charging current maximum to 600A, this is very scary, according to 3.5 / flat experience to project, the cable should also be at least up to 170 flat, this so big cable is unacceptable, whether the weight or loss, thermal failure This is unacceptable, whether the weight or loss, thermal failure, bending radius, etc., so the high current brings heat loss and problems or more, so we need to reduce the heat loss of the cable, the more popular practice is to use the liquid cooling method, its principle is not so complicated, set up a special circulation channel between the cable and the charging gun, the channel to add the cooling liquid to play a role in heat dissipation, through the power pump to promote the circulation of liquid so as to bring out the heat But it's not that easy to get this right, because there are more issues involved and most of the people involved in the development of this product in China still don't have enough knowledge.

The picture above shows the HPC from PHOENIX

Above: TESLA's HPC

There are already many domestic manufacturers doing this product, AVIC Optoelectronics, Star Charging, etc. have launched their own liquid-cooled charging interface, foreign Phoenix, HS, etc. also have their own products, in fact, in the end is the management of heat, I remember the previous DC charging gun development, thinking about how to add T-S to the DC contact, the purpose is actually to be able to detect real-time The temperature difference between your T-S and the plastic may cause major problems in unexpected situations; therefore, temperature management is a very important topic; liquid cooling charging is basically limited to a unidirectional liquid cooling cycle from the facility end to the vehicle end, but in fact, I think the vehicle end can also be viewed together with the battery system cooling, thus realising a two-way liquid cooling cycle. For thermal management, I think it is worth studying how to simulate the heat loss in the whole high-voltage transmission path, which requires a lot of model substitution calculations, and finally come up with a relatively reliable curve.

The above diagram is from TE's HPC

Self-drawn diagram above

For liquid-cooled charging interfaces, I think there are 2 elements that are very important.

One is the temperature management described above, and the other is the management of protection, because you add liquid-cooled pipes, you need to prevent wear and tear leaks, (Tesla has had this problem before, HS seems to have had similar problems,) and you also need to detect the fluid pressure, because the cooling cycle requires a certain fluid pressure to drive the flow of coolant to take away the heat; both of these elements are very complex and not that easy to solve, but it is gratifying to find that when communicating with some of my peers in China, many manufacturers are putting effort into studying these elements.

High power standards:

We know from online sources that our future high-power charging standards will be differentiated according to passenger cars and buses, and the technical objectives will be different.

The long-term target for passenger cars - charging voltage 1000 (1500) V charging current: without cooling, maximum current 120 A, power 120 kW; with cooling, maximum current 400-500 (600) A. The interface standards are forward compatible. This means that basically our high-power standard interface is to be redeveloped, while the original version 15 is to be retained.

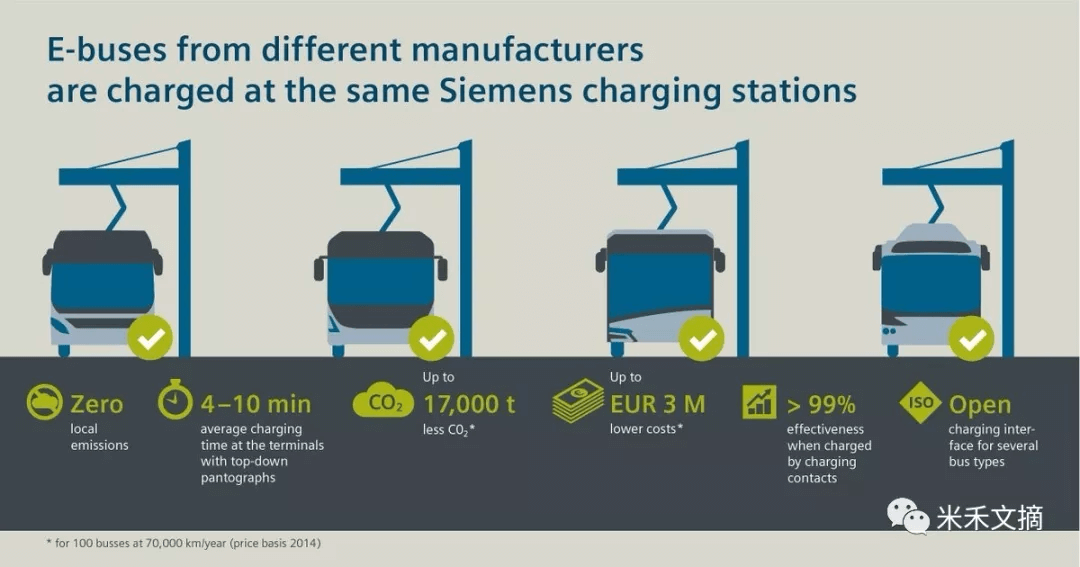

Electric buses - long term goal, terminal charging: 2015 version interface or high power charging interface. (3) Forward compatible solutions

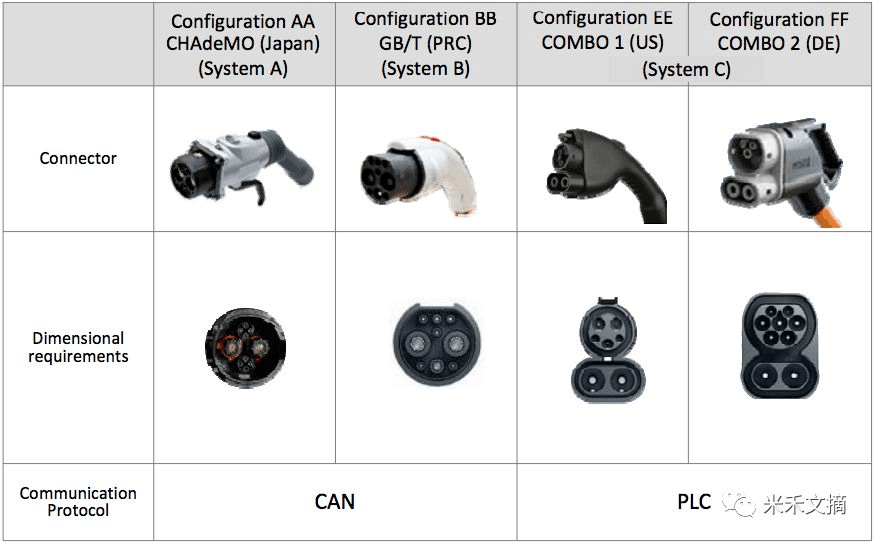

The high power charger will be equipped with both high power charging and version 2015 interfaces, which can be accompanied by a matching interface adapter, and can continue to use version 2015 charging on existing charging equipment. The guide circuit is forward compatible and continues to use the same CAN physical interface as the 2015 version, the adapter only completes the physical size conversion and the cost is kept very low.

So we see that our standard is relatively comprehensive, in the high power charging of buses, also includes the "pantograph" charging, Europe, Japan also have this bus products, the Japanese for the pantograph products are also purchased from the Europeans, the standard is also in the drafting stage, we also have similar products, and buses in operation.

At present the global charging standards can be roughly divided into five categories, namely Japanese CHAdeMO, Chinese GB/T, American COMBO (CCS1), European CCS and Tesla's own standards. As mentioned above, our new high-power charging standard is planned to be developed jointly with Japan, and there is a similar prototype interface product out at the moment, because both China and Japan are using CAN communication, so the way forward depends on which physical interface will eventually be implemented in accordance with the recommendations of which party; currently there are two camps of CAN and PLC.

I think the future may be more flexible in terms of what kind of charging method is used, not necessarily limited to a certain kind of charging method, and there may even be a possibility of power exchange (of course, I personally think this is not mainstream).

Summing up.

High-power charging does not mean that the vehicle can be fully charged immediately within a few minutes, but in a short time using a larger power to the vehicle full of the desired range, closer to the habits and state of the consumer fuel car refueling, of course high-power charging for the safety requirements of the battery is also higher, 5C above the charging time is very short, but the issue of temperature is still a relatively serious topic, especially most The lithium battery used in most passenger cars is less "sensitive" to temperature, so in the medium term, our charging is more about increasing the current while reducing the temperature; in the long term, we should choose to increase the voltage platform of the vehicle, we see that foreign countries are also leaning on the voltage platform of 1000V and 1500V in the future (as a connector development manufacturers practitioners, our next generation of connectors also in the voltage of 1500V), of course, if the voltage platform to improve, involving a lot of electronic components of the re-selection, because many of the components in the 1000 ~ 1500V platform is still difficult to have a good commercialization of the cost space, so this requires the various manufacturers themselves to work hard.

Finally, there is an article on the front end of the internet that is of interest to many people, mainly about the various problems and safety hazards of the ev charging stations currently on the market, I personally think that some of the content in the article is more objective, but some of the content is "amateurish", for example, 750V, which is the standard voltage, that is to say, without high voltage, almost The AC diffuse charge basically takes 7-8 hours, so ask the consumer who wants to buy an electric car. Many times it is not that these manufacturers do not do a good job, but also not to rise to the national "jerry-built" hat, mainly because of the cost of the problem, the whole car industry chain downstream is compressed quite a lot, so if you want to live, a lot of performance indicators are "neutered So if we want to survive, many performance indicators are "neutered". So I think that instead of exposing these problems, we should reflect on the rules of the game of the whole automotive industry, we have gone 30 years ahead, and now after another ten years or so... It's time for us to feel the "stones" of crossing the river.

Luoyang Grasen Power Technology Co., Ltd is a professional AC home charger and DC fast charger EV supercharger manufacturer for 11 years in China, the charging connectors can be any two of CCS1/CCS2/CHAdeMO/GBT. Please enter our website for more information: https://www.grasen.com. Please send email to sales@grasen.com for inquiry.

-- Marcus Groll,A Charging Station Owner in UKRAINE

Start your EV charging station businesses with Grasen. For a no-obligation quote, hit the button below, fill in your details, and we’ll get back to you.